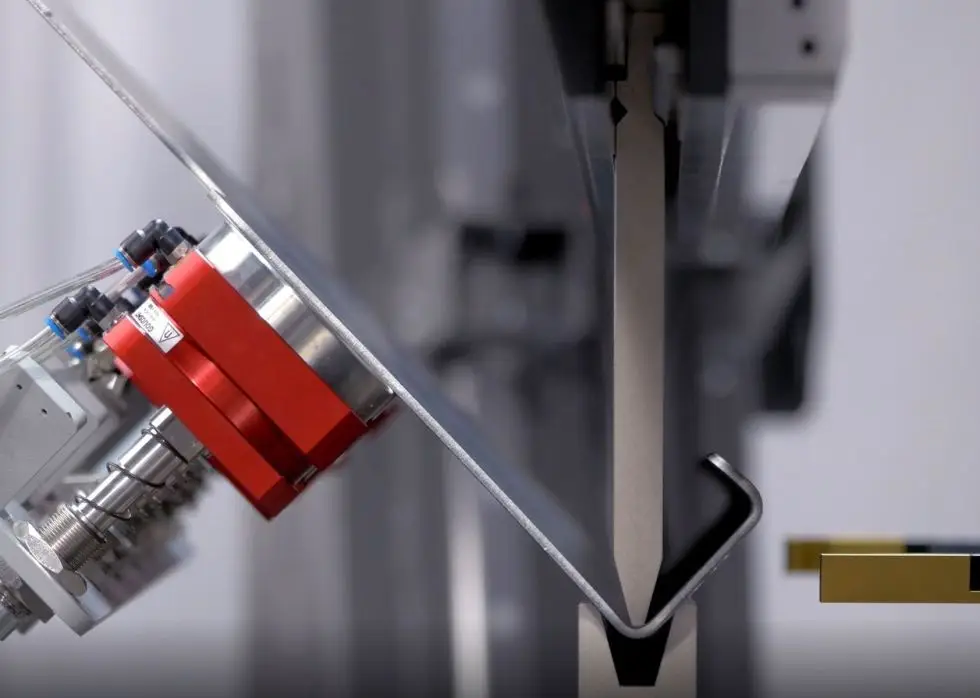

Precision & Consistency

Our manufacturing process includes rigorous quality checks, starting with a first-part inspection and spot checks throughout production. We maintain precise tolerances across our laser-cutting and bending operations, so every part meets your specifications. If your project requires unique tolerances, we’re here to accommodate.

Quality Finishes

We understand the importance of a clean, high-quality finish for parts that need to look as good as they perform. We offer multiple finishing options, including linear finishes using various grit levels (80, 120, 180), applied through our wide-belt sander, which accommodates parts up to 1000mm wide. Our orbital sanding and deburring techniques soften edges and create a professional, smooth surface, brightening the cut face and hiding scratches for a refined look.

Fast Lead Times

Time matters, and at Yar Metal, we’re committed to delivering fast lead times for projects large and small. With many parts ready within just a few days, we keep our processes efficient so you get what you need when you need it. For larger orders, we offer secure packaging and crating options to ensure that every part arrives in perfect condition.

Trusted Expertise

With years of experience and continuous investment in advanced technology, we’ve built a reputation for reliability and innovation. Our team combines technical skill with industry knowledge, allowing us to meet the high standards of clients across various sectors.

Crafting a Sustainable Future

At Yar Metal, sustainability isn't just a commitment—it's the foundation of how we operate. From state-of-the-art manufacturing processes to responsible resource management, we are dedicated to shaping solutions that are as eco-conscious as they are precise.

Innovative Manufacturing for a Greener Tomorrow

Our advanced manufacturing techniques prioritize efficiency and sustainability. By minimizing waste, optimizing energy use, and integrating intelligent automation, we ensure that our operations have a reduced environmental footprint. At Yar Metal, we continuously explore new ways to innovate, staying at the forefront of green manufacturing while maintaining the high-quality standards our clients expect.

Powered by Green Energy

By investing in renewable energy sources such as solar power, we’ve significantly reduced our reliance on fossil fuels. This shift not only lowers our carbon footprint but also demonstrates our dedication to cleaner, more sustainable manufacturing practices and our Net Zero Energy goal.

Choosing Yar Metal means partnering with a company that prioritizes eco-friendly energy solutions, ensuring every project contributes to a greener planet.

Responsible Resource Management

Sustainability starts with the resources we use. We source materials from environmentally responsible suppliers who share our vision of a greener future. Every step of our production process is designed to reduce waste and maximize recycling, ensuring we leave a lighter footprint on the planet. By focusing on resource conservation, we’re helping preserve natural resources for generations to come.

Advanced Material Recycling and Circular Economy Efforts

Our commitment goes beyond production—we’re driving change within the industry. Every scrap of metal generated during fabrication is carefully recycled and reintroduced into the supply chain. By promoting a circular economy, we reduce waste, extend the life cycle of materials, and contribute to a more sustainable metal fabrication ecosystem.